Outline

| Trade name | Yoneyama Waterjet Cutting, inc. |

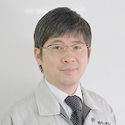

| Representative | Representative Director Toshiomi Yoneyama Person called advisor Kenji Yoneyama |

| Location |

Head Office (Office / Head Office Factory) 〒190-1222 24-10 Higashimatsubara, Hakonezaki, Mizuho-cho, Nishitama-gun, Tokyo 190-1222 TEL:+81-42-556-2358 FAX:+81-42-556-2131 Arai factory (2nd factory) 21-6 Higashi Matsubara, Hakonezaki, Mizuho-cho, Nishitama-gun, Tokyo URL:https://www.yoneyama.co.jp/en/ E-mail:wj@yoneyama.co.jp |

| Founding | May 1975 |

| Founded | may 1980 |

| Capital | 15,750,000 yen |

| Employee | 9 people |

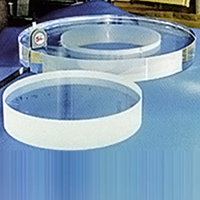

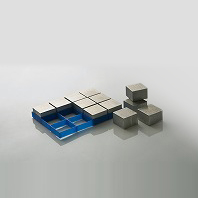

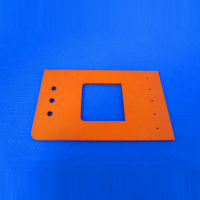

| Business description | Waterjet contract processing |

| Main equipment | 4 water jet machines (with abrasive and hydro) Machining center, milling machine, ultrasonic cleaner, barrel polisher, rotary deburring machine, hot air dryer, CCD measuring instrument, etc. |

| Main activities | Environmental improvement activities (Acquired ISO14001 certification in 2004 when activities started) BCP Voluntary Activities (Participated in the Tokyo Metropolitan BCP formulation project and started activities in 2011) 5S voluntary activities Voluntary quality control activities |

| Major awards | 13th SME Excellent New Technology / New Product Award Received “Excellent Award” in Technology / Product category (2001 Asahi SME Promotion Foundation, Nikkan Kogyo Shimbun) Approved as 300 healthy manufacturing companies (Ministry of Economy, Trade and Industry, SME Agency 2009) |

| Main development | Development of a bending machine for lightweight profile (aluminum square tube, etc.) (1999-2003) Tokyo Metropolitan University of Science and Technology (current Tokyo Metropolitan University) In 2000, the Tokyo Metropolitan Small and Medium Enterprise Promotion Corporation is eligible for subsidies for management and technology activation (Industry-Academia) |

History

| May 1975 | Kenji Yoneyama started processing molds for printed circuit boards as a personal business |

| May 1980 | Reorganized as a legal entity Established Yoneyama Waterjet Cutting, inc. |

| May 1981 | Moved headquarters factory to current location as business developed |

| August 1984 | Along with business expansion, the factory was expanded and the capital was increased to 6 million yen. |

| April 1985 | Sequential introduction of OA / NC equipment |

| January 1990 | Introduced water jet processing machine (SWS4125) and started contract processing |

| August 1991 | Reorganized as a corporation |

| August 1992 | Increased capital to 10 million yen |

| April 1997 | Introduced water jet No. 2 (SWS4125) (started operation of two water units) Started development of shape and shape bending machine |

| April 1999 | Completed lightweight shape bending machine and started contract processing |

| December 2001 | Large R lightweight shape bending machine completed成 |

| March 2002 | Introduced water jet No. 3 (SWS1100) (started operation of three water units) Started precision water jet processing |

| January 2003 | Started selling standard products for bending aluminum square tubes |

| December 2003 | Introduced Water Jet Unit 4 (SWS4425) (Abolished Unit 1) |

| October 2004 | Acquired environmental ISO14001 certification |

| January 2005 | Introduced Water Jet Unit 5 (SWS4425L) (Abolished Unit 2) |

| April 2007 | Established Waterjet Processing Laboratory |

| August 2008 | Toshiomi Yoneyama assumed the position of President |

| December 2013 | Second factory (Arai factory) opened |

| March 2014 | Increased capital to 15.75 million yen |

| March 2014 | Introduced water jet No. 6 (SWS4643) at the Arai Plant (started operation of four units) |