Please leave it to us about the water jet cutting!

As a pioneer of water jets, we have had various experiences and challenges from many customers since opening.

Yoneyama is a proposal-type subcontracter that continues to innovate with ideas and ingenuity.

With abundant cutting results and cutting know-how, we can handle R&D (small lot) to mass production.

Yoneyama's water jet cutting process

Yoneyama's Features

There are about 700 customers including industrial, medical, construction and research institutions.From all over Japan to overseas.

Yoneyama's processing is a craftsman's water jet processing by a skilled engineer following the "water jet theory".

-

More than 30 years specializing in water jet processing.

We solve problems with a wealth of experience and know-how.We introduced a water jet processing machine in 1989, and since then we have received more than 1,000 consultations as a water jet subcontractor. Currently, we can handle 40-50 customers a month.

Take a closer look at Yoneyama's features

-

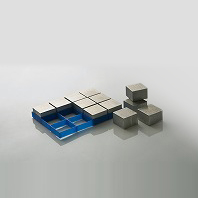

Four water jet processing machines.

Quick delivery are possible.We have four water jet processing machines that can handle a variety of projects, from small lots to mass production such as destructive inspection. Please consult us about projects rejected by other companies.

Take a closer look at the four-machine system

What is water jet processing?

The principle of water jet machining is water flow ejected at ultra high pressure and ultra high speed. Since the water is household effluents and the abrasive is natural stone, it is said to be environmentally friendly without factory effluents.

Water jet cutting is available for various materials

Water jet is available regardless of soft materials / hard materials, single materials / composites, metals / non-metals, energized / non-energized materials.

It is especially suitable for the processing of functional materials and new materials including elements such as difficult-to-cut, fragile, composite and laminated.

-

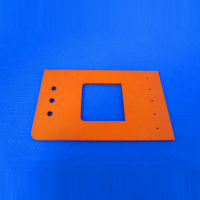

CFRP + aluminum laminated board

This is an example of processing a composite material of CFRP and aluminum laminated board.

Click here for detailse

-

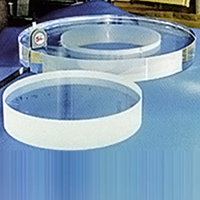

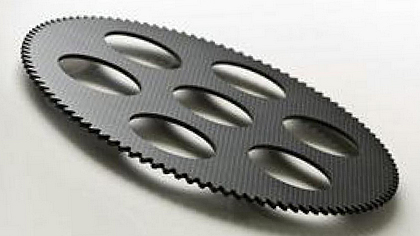

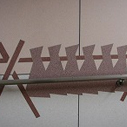

Diamond wheel grooving

Diamond wheel: Diamond layer 8t + aluminum pedestal 40t x φ450 slit 3...

Click here for detailse

-

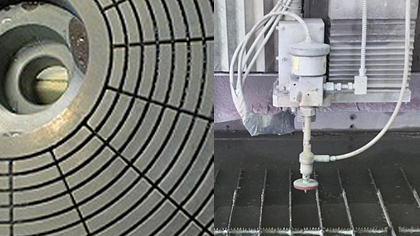

CFRP (Reinforced Plastic / Abrasive Cutting) φ290mm × 3t

Thickness 3.0t x Outer diameter 290, 1-φ50 Center hole, 6-φ50 (PCDφ150) [mm]...

Click here for details

-

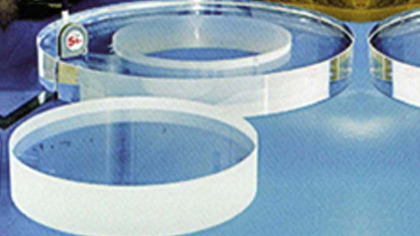

Crystallized glass wall material

Original plate size 900 × 900mm × 20mm thickness Product size approx. L1750 × H700mm...

Click here for details