Suitable for many materials regardless of the material of the workpiece

Processing is possible regardless of differences between soft materials / hard materials, single materials / composites, metals / non-metals, energized / non-energized materials. It is especially suitable for the processing of functional materials and new materials including elements such as difficult-to-cut, fragile, composite and laminated.

-

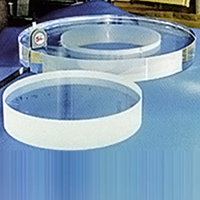

- SIC, Alumina, Ceramics

-

- Aluminum

-

- Carbon / CFRP

-

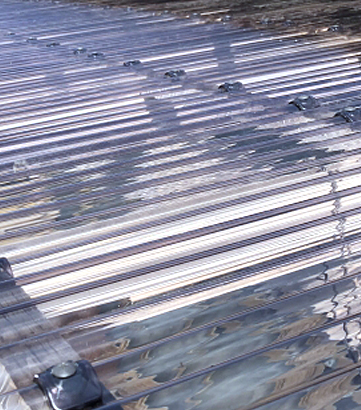

- Glass

-

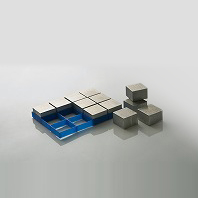

- Titanium / Nickel

-

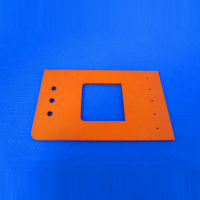

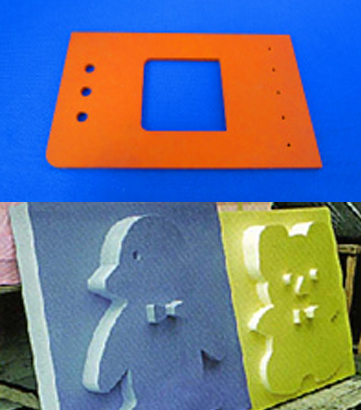

- Polycarbonate / PVC

-

- Porous body / sintered body

-

- wood

-

- Foam resin

-

- Stone

-

- Composite material

-

- Copper / Brass

List of compatible materials for water jet processing

| Material | Cutting | Drilling | Halfway | Peeling | Remarks | Processing example |

| Titanium / Nickel | – | There is no waste in material collection | – | |||

| Copper / Brass | – | No thermal distortion | – | |||

| Aluminum | – | Thin sheet is effective for layering | – | |||

| Composite / laminate | – | – | Combination is free | – | ||

| SIC ・ Alumina ・ Ceramics | – | Effective for hard materials | – | |||

| Carbon / CFRP | – | Various cuttings such as C / C are possible. | – | |||

| Porous body / sintered body | ○ | – | No chipping or chipping | – | ||

| Titanium / Nickel | – | There is no waste in material collection | – | |||

| Glass | – | Compatible with various types of glass (except tempered glass) | – | |||

| Polycarbonate / PVC | – | No melting, dripping or toxic gas | – | |||

| Foam resin | – | – | No crushing due to processing | – | ||

| CBN diamond wheel | – | Grooving into the diamond wheel | – | |||

| Stone | – | Effective for inlaying | – | |||

| wood | – | Compatible with various kinds of wood such as plywood and natural wood | – |