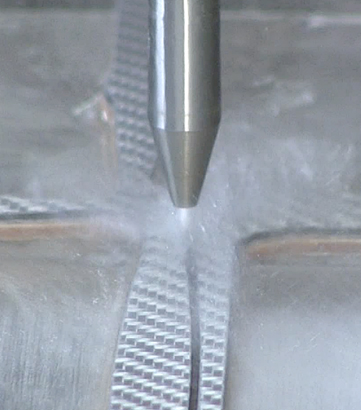

Water jet specialty

We are a company specializing in water jet contract processing.

In 1989, we introduced a water jet processing machine and started “contracted water jet processing”. In 1993, “water jet processing” became our main business, and since 1996, it has officially become “specialized water jet processing contract”.

The number of customers is about 700, and 40 to 50 customers per month are available.

The region accepts more orders from customers in all industries in Japan (partially overseas), industrial, medical, construction, research institutes, etc.

In addition to manufacturers, trading companies, and processors, we can handle various types of business such as institutions and individuals.

Please feel free to contact us when ordering “water jet machining”.

Rich experience and know-how

We have abundant processing experience and a lot of processing know-how.

Over 30 years since we started “contracted water jet processing” in 1989, we have had various experiences and challenges from many customers.

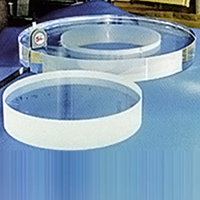

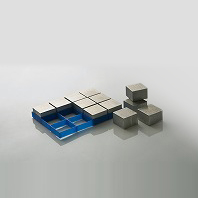

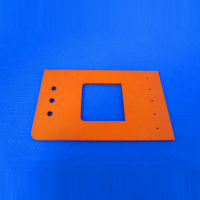

Processed materials include steel such as titanium, nickel and SUS, non-ferrous metals such as aluminum, copper and brass, resin and plastic such as CFRP and polycarbonate, ceramics such as Sic and alumina, glass, silicon, ferrite, porous body, honeycomb and stone・ We have experience in processing various materials such as fragile materials such as wood and cloth, and soft materials such as urethane foam and silicon foam.

Processing methods include cutting, drilling, grooving, surface peeling, and deburring.

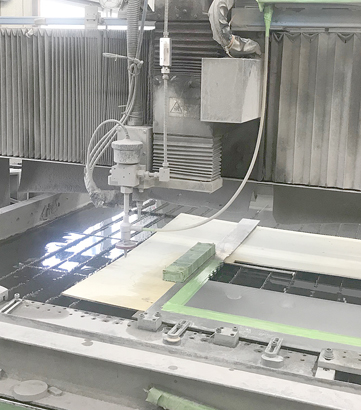

Four water jet processing machines

We have 4 water jet machines. Quick delivery and quick delivery are possible.

Yoneyama Seisakusho has 4 water jet processing machines for various projects such as same day, mass production, small lot and destructive inspection. It corresponds.

-

We will respond with the optimal model that you requested.

Select the optimum model according to the material properties, size, quantity, etc. Pull out the advantages of each device with different characteristics.

-

We respond to urgent and emergency items

By adjusting the processing with three units, it is possible to respond to “Emergency / Emergency” without interrupting other projects.

-

Corresponds to large quantities

By adjusting with 3 units, it is possible to deal with “mass items” without interrupting other projects. In addition, we can reduce delivery time by using 3 units.

-

We do not cause trouble by repair, malfunction

There is no “interruption” by performing periodic maintenance with rotation. Even if an unexpected failure occurs, the remaining two units can handle it.

-

Energy saving operation with dual pump

Water pumps that generate ultra-high pressure water use a lot of electricity. We operate “Dual Pump”, which operates two devices with one pump. Power consumption is halved, contributing to power saving.