Principle of water jet machining

What is water jet processing?

-

Principle of water jet machining

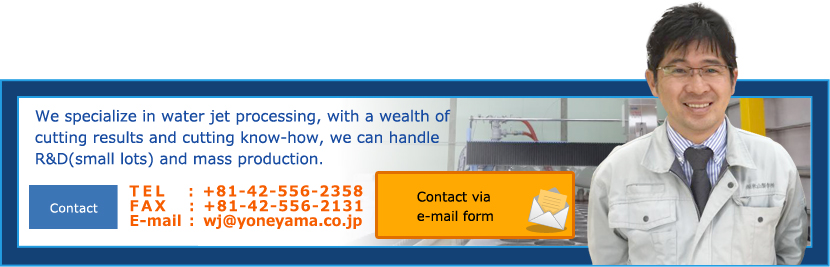

A “water jet” is a stream of water that has been pressurized to ultra-high pressure and ejected at ultra-high speed. “Water jet processing (water cut)” means using this ultra-high pressure and high speed water such as “cutting (cutting), drilling, grooving, peeling, deburring, hanging, drilling, shot peening, cleaning, stirring” Processing method or processing system that performs them.

Water jet processing for industrial product manufacturing

-

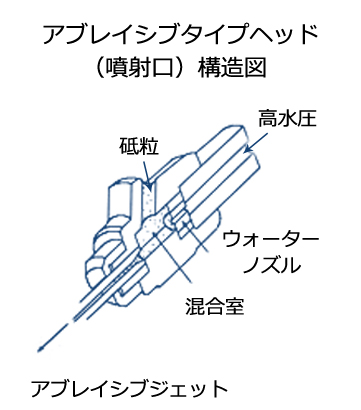

Abrasive machining to process harder materials with high accuracy

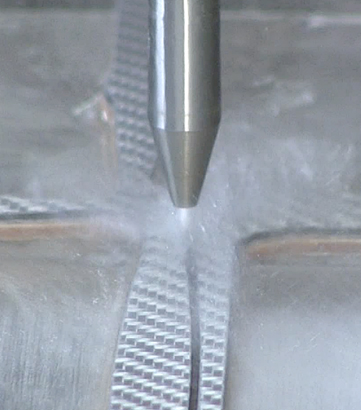

A general water jet system in the industrial product manufacturing field filters tap water with a micron filter, pressurizes it to about 320 MPa with a dedicated high-pressure pump, and speeds Mach 2 through a hole (water nozzle) around φ0.1 to 0.3 mm. Generates a thin high-speed water flow of about 3

Abrasive material (abrasive grains) was mixed at the tip of the water flow around φ0.1-0.3mm and attached to the tip. Abrasive construction method that cuts with water flow from a nozzle (mixing nozzle) of about φ1mm It is called jet processing (commonly called water jet processing, processing with abrasive).Hydro jet machining

For abrasive jet machining, a cutting method that does not include abrasives and cuts with a thin water flow of around φ0.1 to 0.3 mm. This is called hydro jet machining (commonly known as hydro machining or water-only machining).

Features of water jet machining

Water jet processing has the advantage that it does not affect the material function with little heat influence.

Water jet machining has different features from other machining methods

-

- No or little thermal effect on the material due to processing

- No or no stress on the material due to processing, so no stress remains

- There is no modification or alteration of the material due to processing, and it does not damage the material function.

-

- Due to the above features, no toxic gases or new compounds are generated.

- The above features do not cause distortion in the material

- The above features make it easy to process soft materials, thin materials, and fragile materials.

-

- Hard and tough materials can be processed

- Various materials can be processed by the above features.

- The above features enable processing of composites and laminates

-

- Processing such as deburring and peeling is possible by adjusting the water flow.

- Since the water flow is tap water and the abrasive is natural stone, it is environmentally friendly

- Because it is processed with water and natural stone, oils, additives, cleaning agents, etc. are not used for processing and post-processing.

Water jet processing can process various materials.

Water jet processing can process various materials regardless of material.

-

- Processing is possible with metal, plastic, glass and ceramics

- Capable of processing from soft materials such as sponges and gels to hard materials such as superalloys

- Capable of processing from 0.1mm thin film to 300mm thick metal and products

-

- Natural materials such as wood and stone can also be processed

- Can process multiple materials such as composites and laminates

- Cutting of household appliances and equipment modules is possible

Introduction of classic water jet processing

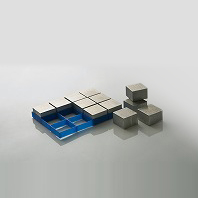

- Titanium, nickel, aluminum, copper, brass, SUS etc.

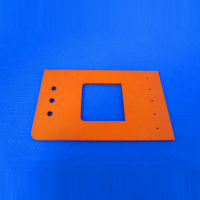

- Inner and outer shape cuts of plastic plates such as polycarbonate, PVC, acrylic and forex

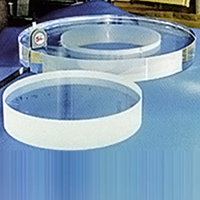

- Internal / external cut of glass, mirror, stone, ferrite, ceramics, sintered body, porous material

- CFRP, GFRP, ultra-high strength polyethylene fiber, aramid fiber material cut

- Cutting of various rubber, foamed resin, cloth material, MDF, delanium, lion board, honeycomb material, etc.

- JIS test piece production of metal and plastic

- Cuts for internal evaluation of products (periodic confirmation, defect confirmation, exhibition, development, teardown, nondestructive inspection confirmation, etc.)

Water jet applied processing / special processing

- Surface peeling, deburring, etc.

- Drilling 5000 glass holes

- Cut sample (structure confirmation, etc.)

- Thin plate stacking of 0.5 mm or less

- Effective processing of rare metals such as titanium

- Laminate cutting of different materials

- Various cutting processes regardless of the material

Processing case

-

CFRP + aluminum laminated board

This is an example of processing a composite material of CFRP and aluminum laminated board.

Click here for details

-

Diamond wheel grooving

Diamond wheel: diamond layer 8t + aluminum pedestal 40t x φ450 slit 3 …

Click here for details

-

CFRP (carbon fiber reinforced plastic)

Thickness 3.0t × Outer diameter 290, 1-φ50 Center hole, 6-φ50 (PCDφ150) [mm] …

Click here for details

-

Crystallized glass wall (Neoparier)

Original plate size 900 × 900mm × 20mm thickness Product size about L1750 × H700mm …

Click here for details