Abrasive jet machining is a process performed by mixing and spraying abrasives into a water stream.

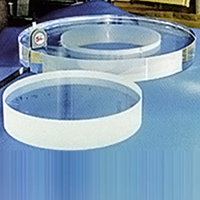

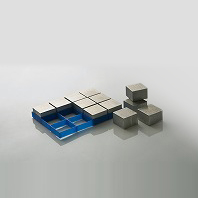

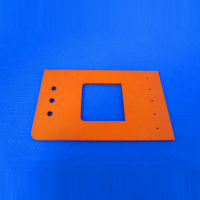

Various materials such as metal and hard rubber can be processed without thermal effects, processing stress, and alteration. It is often effective for new materials such as CFRP, special alloys, and ceramics.

Utilizing the advantages of waterjet’s powerful penetrating force, no thermal effect, no processing stress load, no alteration and alteration, and non-contact processing, cutting of composite materials and laminates of various materials, production of test pieces, connection and joining -Effective for cutting cross sections for observation of materials, parts, and products, such as checking the state of adhesion, welding, fitting, and crimping.